SPITTAL HISTORY

|

|

SPITTAL HISTORY |

THE FLAGSTONE INDUSTRY

From the time of the Hospital and Chapel until the early 1800's Spittal was a fairly quiet farming community,

|

but around this time Sheriff James Traill began to develop a new industry in Caithness by exploiting the local flagstone. |

|

The work was very labour intensive with only a steam engine to pull the spoil up to the top of the heaps. Even cutting the stones to size was done with hand saws. A flat strip of steel about 4 feet long and 4 inches wide clamped between two wooden handles was the saw. This was pulled backwards and forwards by two men, with sharp sand and water applied to the cut to wear away the relatively soft stone. When the stone was worn about half way through the waste part was broken off with a hammer and the edge dressed.

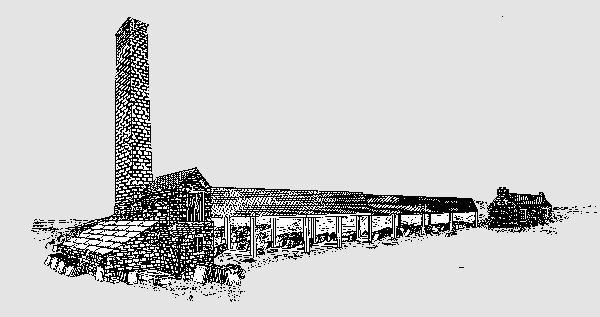

Sometime around 1900 a steam engine was installed to drive bigger saws so increasing production and making the work easier. A chimney approximately 80 feet high had to be built on the end of the stone sawmill building, known locally as The Mill.

The chimney had to be demolished in 1940 after being struck by lightning.

The new steam engine meant that they could now power several saws with blades 16 feet long set end to end enabling a length of 32 feet to be cut. Still the same design of saw blade, steel strip with no teeth, and sand/water abrasive, now dribbled from wooden boxes above the saws. The men now only had to set up the next stones on spare wagons and wheel them under the blades.

The sand used was carted from Leavad, about 6 miles South, where a massive soft sandstone boulder had been left after the Ice Age. As this sand hadn't been rolled around in sea or river the grains had lots of sharp points and edges, perfect for cutting away flagstone.

The steam engine driving the saws was later replaced by a gas powered engine running on gas produced from coal on the premises, this arrangement was more efficient especially as the old straight bladed saws were replaced by rotating carborundum discs 20 inches in diameter with the stones being moved through underneath on trolleys, this was in use until the Quarries closed in 1933 due to a lack of demand.

In 1946 Major Threipland of Dale, owner of the surrounding estate, bought Spittal flagstone and nearby Achanarras slate quarries. He installed new plant with a diamond bonded circular saw driven by electricity. This could cut much faster and the blade lasted a lot longer so it was a big improvement. This saw was operated up until 1996.

Work is still in progress on this section. Come back soon to see what has been done.